MontaWMS Hardware

In addition to producing software, MontaWMS also supplies and maintains various hardware systems. This hardware is used at the various Monta warehouses to pick orders in the most efficient way. Our own R&D department continuously optimise and expand these hardware systems. Work smart ánd (with) hard(ware).

What is WMS hardware?

WMS hardware and software go hand in hand. Every process in a warehouse is controlled by our software. Orders from MontaWMS are received by our hardware, guiding employees through the process.

MontaWMS’ hardware also makes it possible to record employee actions and update orders and stock levels in realtime. Examples of hardware systems in a warehouse include:

- Android hand scanners (min. 5 inches)

- Barcode scanners

- Put-to-light-systems

- E-check-to-light-systems

- Mezzanine floors

- Windows-based workstations

For the past 20 years MontaWMS has been continuously developing these hardware solutions for optimal integration with our software.

Hardware systems MontaWMS provides

Every warehouse has different requirements, and every process requires different technology. Thanks to our smart hardware, your employees are optimally equipped to perform their tasks efficiently. Does your employee walk through the order picking area with a cart? Do they replenish the pick locations? Or do they stand on the inbound floor checking incoming goods? MontaWMS provides the right hardware for every employee.

Advantages of our hardware systems:

- Smart integration with (existing) business applications

- Connection to Android software + maintenance/updates

- Over 20+ years of continuous development and use in our own warehouses

MontaWMS: your solution to an optimized warehouse

Since 1999, we’ve been perfecting our smart warehousing software – the same system behind Monta’s fulfillment services. Trust our expertise.

75+

Dedicated Developers

2.500+

Connected Webshops

20+

Monta Warehouses

Automation is the future

Our software and hardware solutions make your warehouse employees’ work easier, more fun and faster. Our goal is to minimize the workload for your warehouse employees while increasing efficiency.

Automation plays a major role in this. In our own warehouses, we use automatic packing machines that take over the entire packing process. Watch the video of the Monta PacMan on the left.

In conclusion, hardware and software integration in warehouse operations streamlines processes. It makes work more accessible and enjoyable for warehouse employees, leading to increased efficiency and productivity.

Practical general warehouse hardware

MontaWMS supplies many different types of warehouse hardware. From fixed racking to complete warehouse fittings, we supply everything at competitive prices. But in addition to the solutions we provide, other general hardware systems are needed to manage your warehouse optimally. Below you will find applications that we use every day in our warehouse. They are extremely valuable and definitely worth purchasing yourself.

Barcodescanner

For inbound and outbound, we use one Zebra LI4278 per workstation. This handheld scanner works on Bluetooth. In addition, you also get the base station with a USB connection cable.

Labelprinter

We also use the Zebra ZD420D thermal label printer. The flexible 4-inch label printer is durable and also has above-average performance features.

Computer

For the workstations, you can use an OptiPlex 3080 MFF or similar Windows station. 8GB and higher is recommended.

Touchscreen

We use a touchscreen, the iiyama ProLite T2235MSC-B1. This is a 21.5″ monitor with a completely flat edge-to-edge front.

Labels

We use labels via NoviPrint. These come in two different sizes (item codes E100150102NH01 and E080035102NM01). One is for the shipping label and one is for the coupling label to inbound products to a stock location.

Orderpick scanner

We supply the order picking scanner ourselves. This is a Newland order picking scanner with Android software installed. Our apps always come with maintenance and updates included.

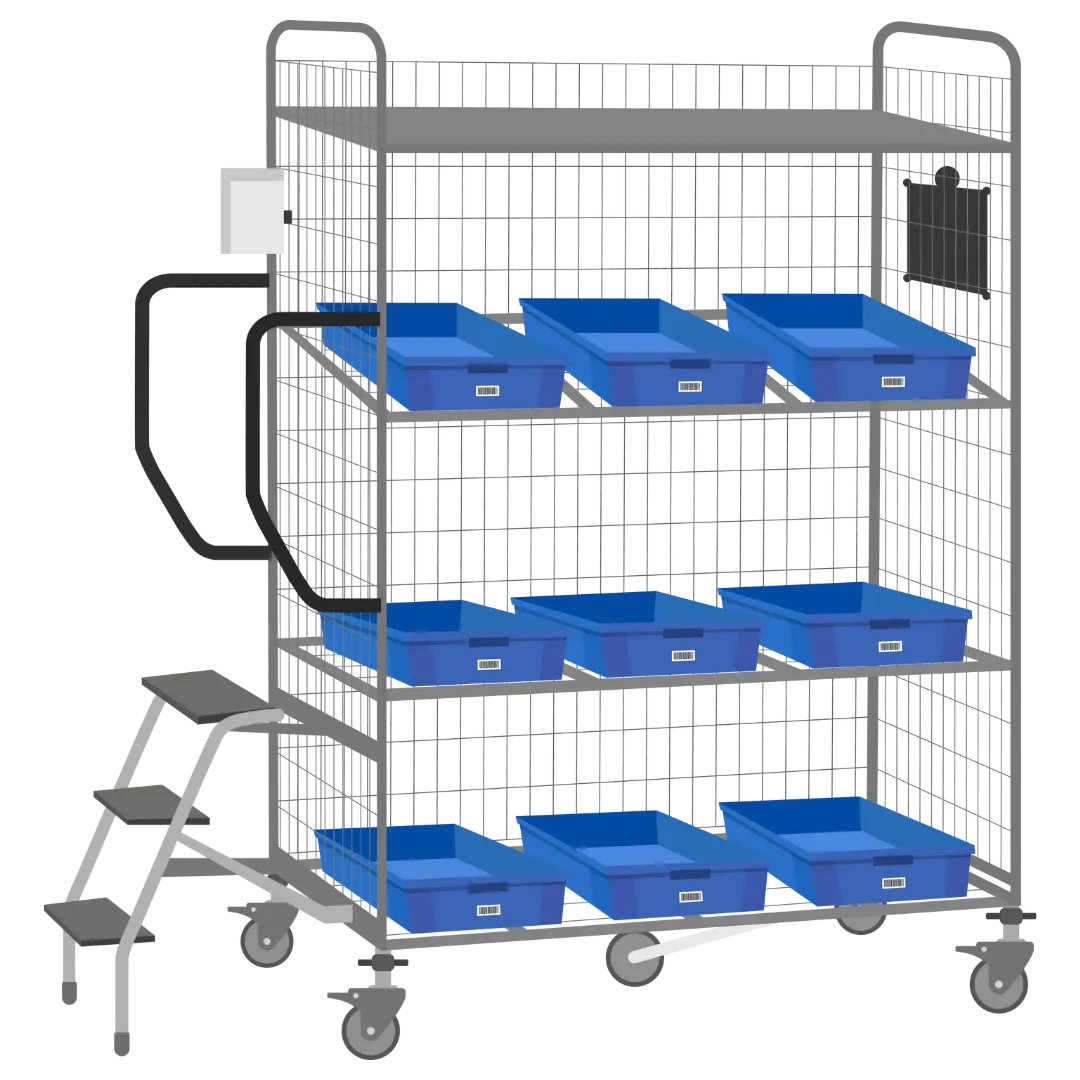

Rolling carts

To pick orders even faster, it is useful to have large rolling carts in your warehouse. We use rolling carts from Engels Logistiek.

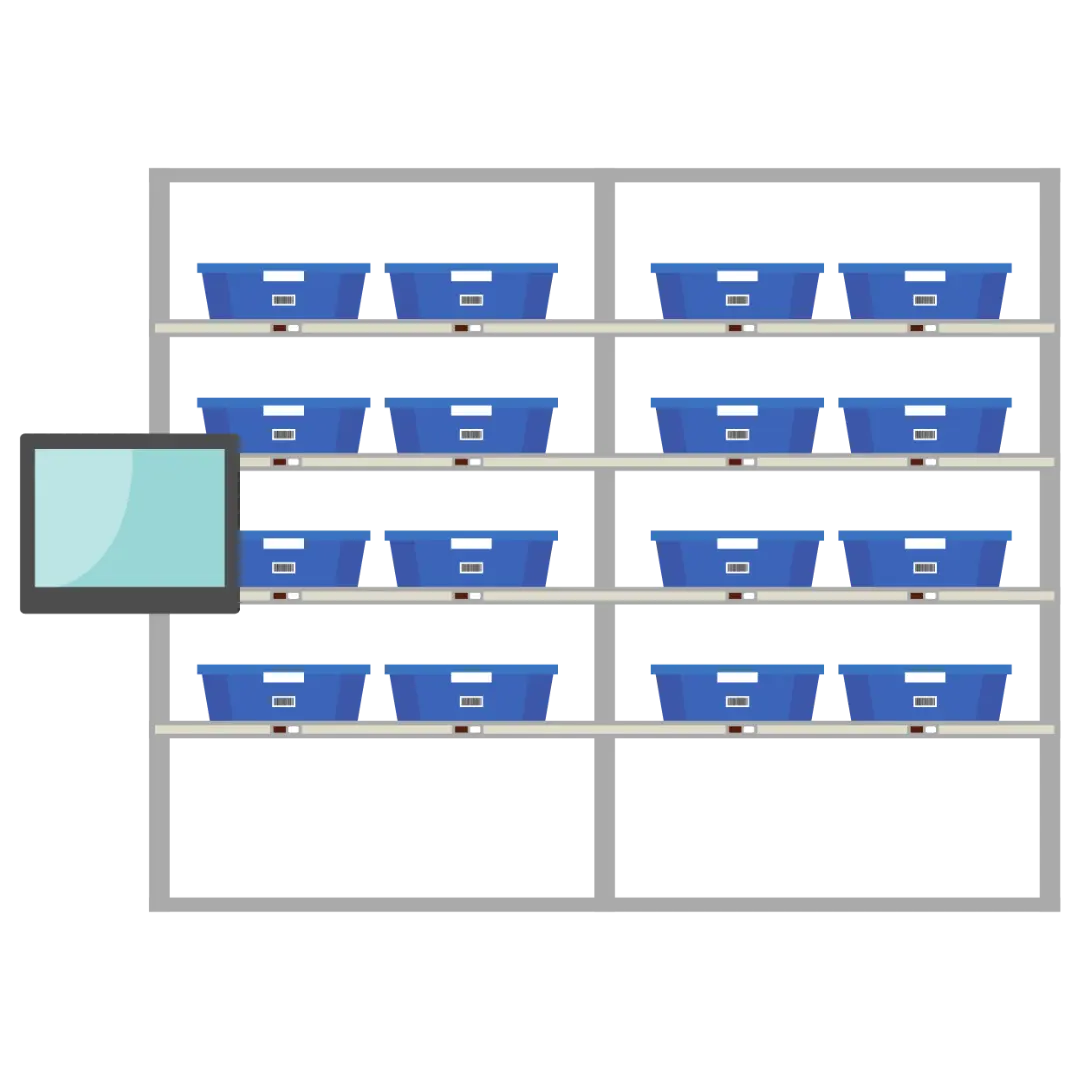

Container racks

We also source our container racks and small crates from Engels Logistiek. These crates are ideal for bulk picking.

Workstations

In addition, we can also supply height-adjustable work tables, spray-painted in any RAL color you desire: for example, your brand color.

Put-to-light-system

To pick orders even faster, it is useful to have large rolling carts in your warehouse. We use rolling carts from Engels Logistiek.

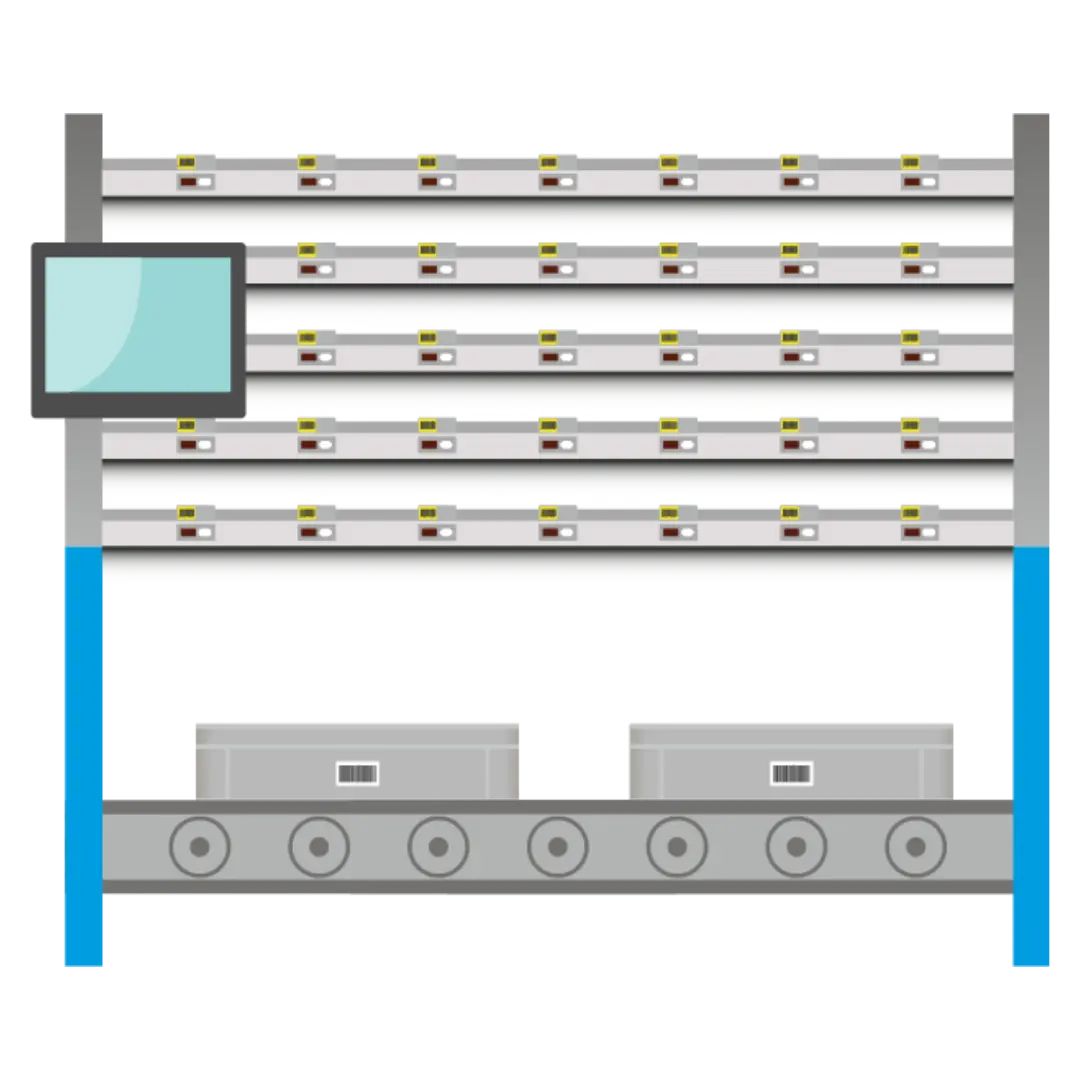

Pick-to-light-system

We also source our container racks and small crates from Engels Logistiek. These crates are ideal for bulk picking.

Integration of robotics systems with MontaWMS

Integrating robotics systems, such as AutoStore and Lowpad, with our warehouse management solution significantly advances warehouse operations.

- Collaborative robotics

This approach allows humans and robots to work together, leveraging the strengths of both to achieve maximum efficiency. - AutoStore integration

Our solution can integrate with AutoStore systems, enhancing storage efficiency and orderpicking accuracy. - Lowpad integration

By integratig with Lowpad systems, our WMS-solution can streamline the movement of goods within the warehouse, reducing manual labor and increasing efficiency.

In conclusion, integrating robotics systems with our WMS streamlines operations and fosters a collaborative environment where humans and robots work together for optimal efficiency.

Choosing the right hardware for your warehouse

Selecting the proper hardware is crucial for the smooth operation of your warehouse, and our solution offers the flexibility to integrate with various hardware types.

- Assess your needs

Understand the specific needs of your warehouse, such as the volume of goods, the speed of operations, number of employees and level of automation required - Consider compatibility

Ensure that your chosen hardware is compatible with your warehouse management solution for seamless integration. - Evaluate quality and reliability

Choose hardware that is durable, reliable and designed for the demands of a warehouse environment. - Seek expert advise

Consult our team of experts, who can provide guidance based on your specific needs and help you choose the proper hardware.

In conclusion, choosing the proper hardware for your warehouse is a critical decision, and our solution’s flexibility allows for a tailored approach that meets your specific needs.

How our hardware has helped: case study Pink Gellac

Our warehouse management solution has been instrumental in transforming operations and boosting efficiency for numerous businesses. For example the pick-to-light-system that boosted the orderpicking process at Pink Gellac:

“The flexibility that Monta offers us is extremely important. Very pragmatic, short lines of communication, solution-oriented thinking, and collaboratively professionalizing end-to-end processes through clear agreements and lean meeting structures. A very pleasant collaboration!”

Sander Groenendijk – CFOO Pink Gellac

In conclusion, this case study demonstrates our solution’s transformative impact when paired with the proper hardware, leading to increased efficiency, accuracy, and productivity.

Frequently Asked Questions about Warehouse Hardware

What is the meaning of warehouse equipment?

Warehouse equipment encompasses all elements, systems, or machines used in logistics tasks within a warehouse. This includes goods receipt, storage, stock management, transportation, order processing, and dispatch. With MontaWMS, these tasks can be seamlessly managed and optimized, enhancing the efficiency and productivity of your warehouse operations.

What type of equipment is commonly used in a warehouse?

Standard warehouse equipment includes barcode scanners, computers, label printers, touchscreens, order pick scanners, roll containers for bulk picking, bin racks, small crates, packing tables, and Put to Light and Pick to Light systems. When integrated with MontaWMS, all these tools contribute to a highly efficient and productive warehouse operation.

What should a warehouse have?

A warehouse should have essential equipment such as forklifts, pallet jacks, hand trucks, and platform trucks, considering the products’ size and maximum load capacities. Additionally, it should include modern hardware like barcode scanners, computers, label printers, and order pick scanners, among others. When these tools are integrated with a comprehensive warehouse management system like MontaWMS, they can significantly enhance efficiency and boost warehouse productivity.

What is logistics equipment?

Logistics equipment refers to the machines and devices used to move products within a logistics operation. This includes Barcode Scanners, Computers, Label Printers, Touchscreens, order-pick scanners, Roll Containers for Bulk Picking, Bin Racks/Small Crates, Packing Tables, and Put to Light and Pick to Light Systems. When integrated with MontaWMS, these tools can significantly enhance efficiency, accuracy, and overall productivity in a warehouse setting.