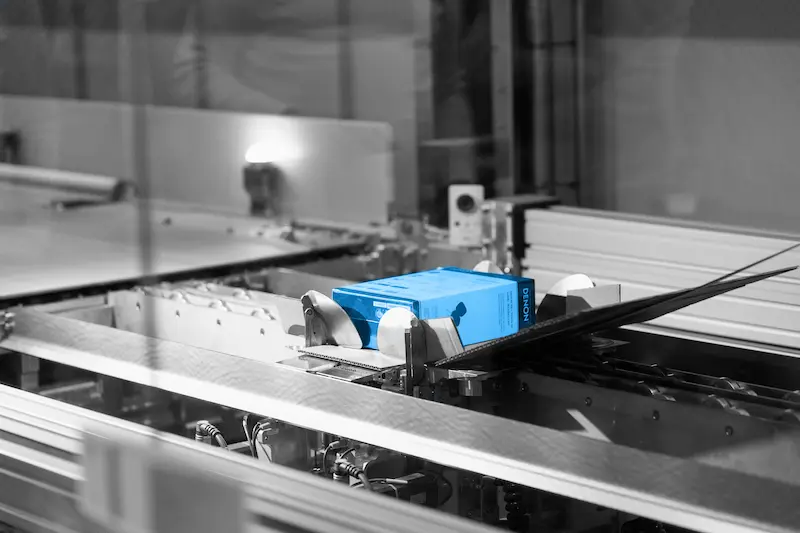

Fit-to-size automated packaging machine

Have you ever wondered how e-commerce businesses manage to send out perfectly packed orders so quickly? The secret lies in the intelligent integration of packaging machines with systems like MontaWMS. These aren’t just tools; they’re game-changers in self-managed warehouses.

Introduction to packaging machines

Explore the dynamic world of packaging machines and their integral role in enhancing warehouse management.

Keep reading to learn how these innovative machines are transforming the efficiency and productivity of e-commerce warehouses.

Understanding packaging machinery in modern warehouses

Let’s delve into how packaging machinery is revolutionising operations in modern warehouses.

- Efficiency in operation: Packaging machines significantly speed up the packing process, reducing manual workload and increasing throughput.

- Automation and its advantages: Automation in packaging brings precision and consistency, ensuring each package is handled with utmost accuracy.

- Types of packaging machinery: From compact, versatile units to large-scale industrial systems, there’s a variety of machinery to fit different operational scales and needs.

- The role of MontaWMS in integrating packaging machines: MontaWMS plays a crucial role in seamlessly integrating these machines into your existing warehouse systems, enhancing overall productivity.

Embracing these advanced packaging solutions can lead to a significant transformation in your warehouse’s efficiency and output.

25+ Years of continuous development

MontaWMS gets a little smarter every day – excellence by experience

75+

dedicated developers

2.500+

connected webshops

20+

Monta warehouses

The mechanics of a packaging machine

Discover how a packaging machine works, from the initial product handling to the final packaging stage.

- Basic operation: Products are placed on a roller conveyor, where they enter the machine to be scanned and packaged.

- Technological integration: Advanced technology calculates the optimal box dimensions, ensuring efficient use of materials and space.

- MontaWMS streamlines warehouse operations by using ‘Pacman,’ a fit-to-size automated packaging machine with conveyors and a WMS.

- Automated precision: Each step, from scanning to packaging, is automated for maximum precision and efficiency.

The intricate mechanics of a packaging machine exemplify how automation and technology can revolutionise the packaging process in industrial settings.

Benefits of using an automated packaging machine

Let’s explore the numerous benefits of implementing an automated packaging machine in warehouse operations.

- Labor and cost savings: Dramatically reduces labour costs by replacing up to 15 manual packaging stations, thus enhancing process efficiencies.

- Increased efficiency and speed: The packaging process becomes much faster and more efficient, handling everything from small books to large vacuum cleaners in a seamless flow.

- Reduction in material waste: Generates fit-to-size boxes, saving up to 20% on cardboard and eliminating the need for void fill.

- Impact on shipping volume and costs: Significantly reduces box volume by up to 50%, resulting in lower shipping costs and less material usage.

Adopting an automated packaging machine is not just a step toward efficiency; it’s a leap toward sustainability and cost-effectiveness in your packaging process.

What our customers say about Monta

“MontaWMS has been a huge success for us. We were among the first to put this outstanding WMS system into operation. Where necessary, we were able to quickly adapt the system to our needs.”

Raymond Vlietstra

Key Manager AkzoNobel

“Monta has long been our fulfilment partner, aiding our joint growth. They supply our stores, handle all online orders and now manage our fulfilment from Germany too. Fantastic!”

Sander Groenendijk

CFOO of Pink Gellac

“We were looking for a partner who understood our ambitions and could keep up with them. We found the perfect match in Monta: scalable, flexible and personal. We can deliver with confidence even during peak periods.”

Nicole Peters

Operations & Supply Chain Manager Stoov

Customisation and flexibility in packaging machines

The versatility of packaging machines lies in their ability to adapt and customise according to diverse product needs.

- Adapting to different product sizes: These machines can handle various product sizes, from small items to larger goods, adjusting automatically to fit each product.

- Customisation for specific industry needs: Tailoring packaging solutions to meet specific industry requirements, ensuring optimal performance.

- Transparent operations and adjustability: Features like adjustable settings and transparent operations make these machines user-friendly and versatile.

- Versatile and user-oriented design: Emphasising the importance of a design that’s both flexible and easy to operate.

With their ability to adapt and customise, these packaging machines offer an efficient, tailored approach to meet the unique demands of different products and industries.

Discover the future with fit-to-size automated packaging solutions and MontaWMS

Ready to transform your warehouse operations with state-of-the-art packaging solutions? Embrace the efficiency and innovation of fit-to-size automated packaging machines, perfectly complemented by the comprehensive warehouse management capabilities of MontaWMS.

Don’t miss this opportunity to streamline your processes, reduce costs, and enhance productivity. Contact us now for more information and to schedule your free demo. Witness firsthand how MontaWMS and our advanced packaging solutions can revolutionize your business. Take the first step towards a more intelligent, efficient warehouse today with MontaWMS.

Frequently asked questions about packing machines

What is a packing machine?

A packing machine is a type of equipment used in the packaging process to automate and streamline the packing of products. These machines can vary in functionality, handling tasks like measuring, filling, sealing and labelling. They are designed to improve efficiency, reduce manual labour and ensure consistent packaging quality. In combination with systems like MontaWMS, packing machines can significantly enhance warehouse operations, offering optimised, fast and reliable packaging solutions suitable for various industries.

What does a fit-to-size automated packaging machine do?

A fit-to-size automated packaging machine customises packaging by creating the smallest possible box for each product, reducing waste and shipping costs. Integrating with MontaWMS enhances warehouse packaging efficiency, ensuring cost-effectiveness and sustainability by optimising material use.

What machine is used for packaging?

Automated packaging machines, such as the fit-to-size automated packaging machine, are widely used for packaging. They are efficient, adaptable and integrate smoothly with MontaWMS to optimise the packaging process for various product sizes and types.

What is packaging machinery?

Packaging machinery refers to machines used in various packaging stages, from initial packaging to preparing products for distribution. This involves fabrication, cleaning, filling, sealing, labelling and palletising. Such machinery is essential in different industries, including pharmaceuticals, where they ensure efficiency and accuracy in packaging. MontaWMS complements these machines by offering advanced management of these processes, further enhancing efficiency and productivity in packaging operations.